MetriTec™ Ultrasonic Thickness Gauge

Product Detail

MetriTec™ Ultrasonic Thickness Gauge M211 and M212 ultrasonic thickness gauge uses the ultrasonic pulse reflection principle for thickness measurement. The instrument can be equipped with four types of probes: standard probe, micro-diameter probe, coarse crystal probe and high temperature probe, and is professionally used for thickness measurement of metals (such as steel, aluminum, copper, etc.), plastics, ceramics, glass and other materials that can transmit ultrasonic waves. The instrument adopts professional timing chip design, the resolution is up to 0.001mm.

In many industries, It is essential to mesure the wall thickness to confirm the condition of the material for the normal running of the items or structure safety. It can be widely used in testing the thickness of various accessories or metallic structure to check them whether to be repaired or changed such as ships, tanks, pipes or steel structure. The gauge is applicable for petroleum, chemical, metallurgical, shipbuilding, aviation and aerospace various fields.

MetriTec™ Ultrasonic Thickness Gauge M213 ultrasonic thickness gauge is easy to operate and uses the principle of ultrasonic pulse reflection to test the thickness of materials. The instrument can be equipped with four types of probes: standard probe, micro-diameter probe, coarse crystal probe and high-temperature probe, and is professionally used for thickness measurement of metals (such as steel, aluminum, copper, etc.), plastics, ceramics, glass, fiberglass and other materials that can transmit ultrasonic waves. The instrument adopts professional timing chip design, the resolution is up to 0.01mm.

FAQ:

What is an ultrasonic thickness gauge?

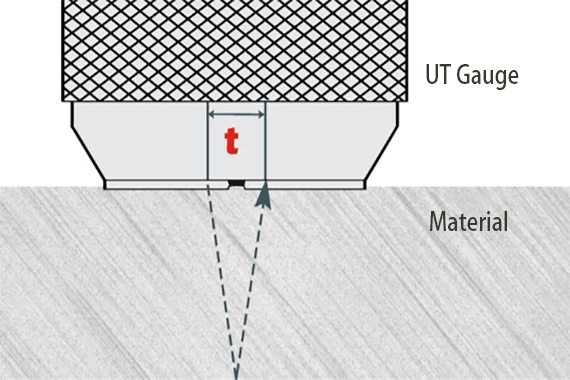

An ultrasonic thickness gauge (ultrasonic wall thickness gauges, ultrasonic thickness tester, ultrasonic thickness meter, UT gauge, etc.) is a precision measuring instrument used to determine the thickness of materials by utilizing high-frequency sound waves. It works by emitting an ultrasonic pulse through a probe (transducer) into the material, then calculating the thickness based on the time it takes for the sound wave to travel through and reflect back. Sound waves reflect from the boundaries between dissimilar materials, and the transducer not only creates the sound pulse, but also listens for the echo.

What's the measuring principle of ultrasonic thickness gauges?

ACS Material ultrasonic thickness gauges feature dual-crystal probe which is consisted of two independent transducers angled, separated by a sound barrier. The instruments use single echo measurement principle. One transducer sends the ultrasonic pulses inside probe which returns after it impacts the back wall and another transducer receives the echo. It calculates the thickness of material by the sound velocity and the time taken between the pulses sent and echo received.

Single-echo UT gauge probes feature a dual element transducer with automatic V-Path compensation. Thickness is determined by measuring the propagation time of the speed of soun , dividing it by two and then multiplying by the velocity of sound for that material.

Why measure wall thickness with ultrasonic thickness gauge and where to use it?

Ultrasonic thickness gauges provide a non-destructive, accurate, and efficient method for measuring wall thickness in various materials. They are particularly useful when only one side of a structure is accessible, making them ideal for inspecting pipelines, tanks, and other industrial components. These gauges help detect corrosion and erosion early, ensuring preventive maintenance and safety. Their versatility allows measurement of both metallic and non-metallic materials, as long as they conduct ultrasonic waves and have relatively parallel surfaces. Additionally, they offer high precision, enabling fast and reliable inspections even in hard-to-reach areas. Industries rely on ultrasonic thickness measurement for quality control and compliance with safety standards, reducing the risk of failures and costly repairs while extending the lifespan of equipment and infrastructure.

The ultrasonic thickness testers are widely used in various industries for non-destructive testing and material quality and condition assessment, including petroleum, chemical, metallurgical, shipbuilding, aviation, aerospace and etc.

1. Industrial Quality Control

Ultrasonic thickness measurement is essential in manufacturing and production processes to verify that materials and components meet precise thickness specifications. Common applications include:

● Metal and plastic fabrication

● Aerospace and automotive parts inspection

● Composite material thickness verification

2. Corrosion and Erosion Monitoring

Many industries rely on ultrasonic thickness gauges to monitor the degradation of materials over time due to corrosion, erosion, or wear. This is particularly important in:

● Oil & Gas Pipelines: Detecting internal corrosion in pipelines to prevent leaks or failures.

● Storage Tanks & Pressure Vessels: Ensuring walls maintain structural integrity to avoid hazardous conditions.

● Boilers & Heat Exchangers: Measuring metal thinning caused by high temperatures and chemical reactions.

3. Automotive & Aerospace Industry

● Vehicle Inspection: Checking the thickness of automotive panels, frames, and components for quality assurance.

● Aircraft Maintenance: Evaluating the structural integrity of airplane fuselages, wings, and other critical parts.

4. Shipbuilding & Marine Industry

● Assessing hull thickness to prevent structural failures due to seawater corrosion.

● Ensuring compliance with international maritime safety regulations.

5. Construction & Infrastructure Inspection

● Steel & Concrete Structures: Measuring the thickness of bridge components, buildings, and tunnels for maintenance.

● Railway Tracks: Detecting material wear in rails to prevent accidents.