V-Shape AAO (5P/Pack)

Product Detail

CAS No.: 1344-28-1

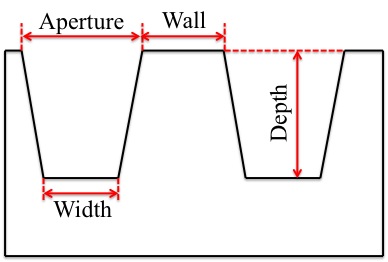

Types of V-Shape AAO Templates

| SKU | Opening Aperture | Bottom Aperture | Hole Depth | Size |

| A3010021 | 90nm | 40nm | 200nm | 2cm x 2cm |

| A3030021 | 300nm | 100nm | 300nm | 2cm x 2cm |

| A3010011 | 90nm | 40nm | 200nm | 1cm x 1cm |

| A3030011 | 300nm | 100nm | 300nm | 1cm x 1cm |

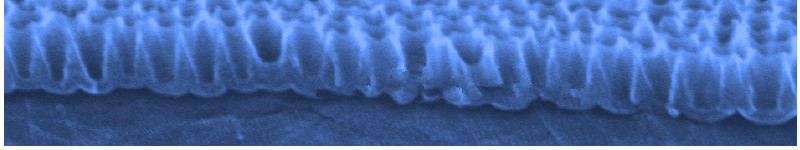

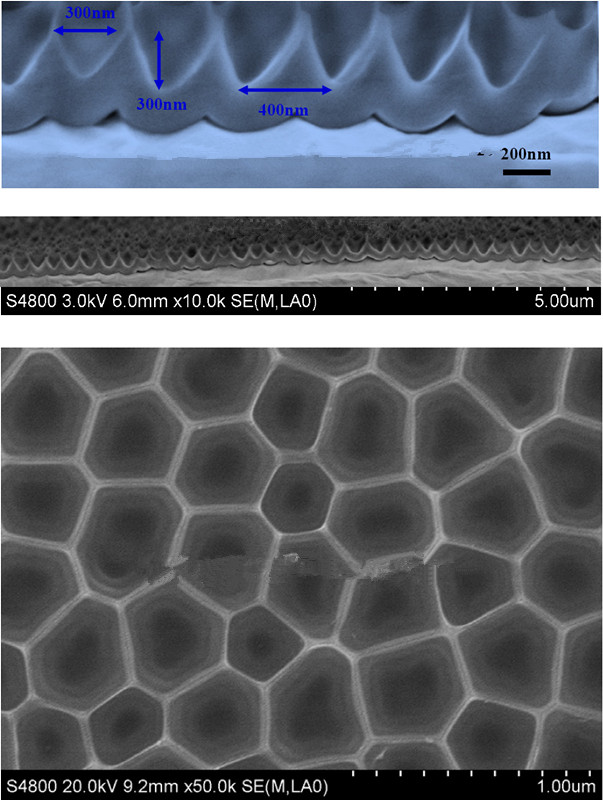

The tapered hole (V) AAO template changes the normal vertical channel AAO template into a structure with large pore size above and small pore size below. The structure is especially suitable for nano surface construction‚ such as nano-imprint lithography. In the release phase of the process‚ V channel has a great advantage over the vertical channel.

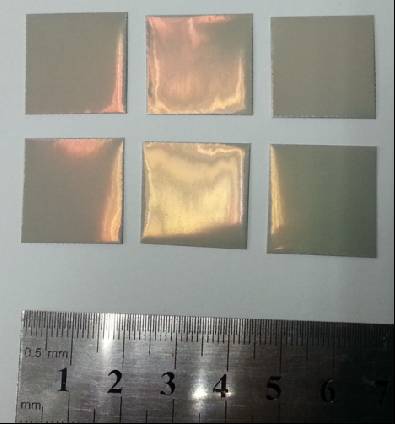

V Shape AAO Templates,2cmx2cm

Disclaimer: ACS Material LLC believes that the information on our website is accurate and represents the best and most current information available to us. ACS Material makes no representations or warranties either express or implied, regarding the suitability of the material for any purpose or the accuracy of the information listed here. Accordingly, ACS Material will not be responsible for damages resulting from use of or reliance upon this information.

FAQ

1. What is the best method to dissolve/etch an AAO Template?

There are two methods that we recommend. Please make the best adjustments based on your own experiment.

Slow Removal: Depending on the microstructure evolution, a slow removal of AAO layer may be preferred. This can be achieved by using 5 wt% phosphate acid at 30º Celsius. Usually, this process is suitable for Single-Pass AAO.

Rapid removal: Use heated 3M NaOH or HCl solution, depending on your specific needs.

2. What's the thickness of the Al substrate?

The Al substrate is 150microns thick.

3. What is the best method for cutting an AAO Template?

The method we recommend involves using a metal ruler, a sharp knife or blade, a clean cloth (specialized cleanroom wipes suggested), and a hard flat surface (glass or steel).

Cutting Method:

1. Cover the hard surface with a cleanroom wipe or clean cloth.

2. Place the AAO sample on the wipe with the Al substrate (back side) facing up.

3. Align the metal ruler parallel to the cut you want to make.

4. Press down firmly on the ruler and slice the AAO sample several times along the edge of the ruler.

5. If the AAO sample is not cut through completely, slowly and carefully bend the template until it comes apart.

6. Finally, the AAO sample can be cleaned by ultrasonic cleaning <30 seconds using acetone, ethanol, isopropyl alcohol or deionized water.

Research Citations of ACS Material Products

- Jaworski, Nazariy, and Nazariy Andrushchak. “A method of nanoporous anodic aluminum oxide structure modeling based on Bezier curves generation.” 2017 14th International Conference The Experience of Designing and Application of CAD Systems in Microelectronics (CADSM), 2017, doi:10.1109/cadsm.2017.7916085.

- Fleming, Evan, Feng Du, Eric Ou, Liming Dai, and Li Shi. "Thermal conductivity of carbon nanotubes grown by catalyst-free chemical vapor deposition in nanopores." Carbon 145 (2019): 195-200.

- Fleming, Evan. "Multi-scale investigation of composite materials for enhanced phase change thermal storage systems." PhD diss., 2018.

- Jaworski, Nazariy, Marek Iwaniec, and Mykhaylo Lobur. "Implementation Features of Fibrous Composite Microlevel Structure Model Construction Based on Bezier Curves Generation and OpenCL Technology Usage." Machine Dynamics Research 41 (2017).

- Liu, Cong. "Nanoporous materials chemistry: From gas separation to high pressure chemistry." (2017).